square hole and dropped a chunk of oak to be used as bench stop. Underneath the oak is another piece of oak

cut as a spiral. This allows me to raise/lower the bench stop in very tiny increments:

I got the idea from "The Compleat Woodworker" Edited by Bernard E. Jones. I highly recommend this book.

Back To Top

Leg Vice:

My sister stumbled across this old wooden thing in what she calls

"The Roadside Boutique"

- people throwing away stuff. She took a

picture, sent it to me, asked me what it is and if I wanted it.

YES!!!!

That's an old Leg Vice. Absolutely go grab it. And now it's a part

of the shop:

The top of the chop is rounded so someday I'm going to saw out a section and replace it with oak.

Back To TopTool Storage

I've tried several methods of tool storage. Some inspired by woodworking magazines. The first method I tried was:The "Tool Board" method:

The boards were hung with French Cleats. This storage method had advantages:

- You could move a board with the tools you need to where you are working.

- You could reconfigure the boards to carry different tools or the same tools different ways.

But the system has one disadvantage:

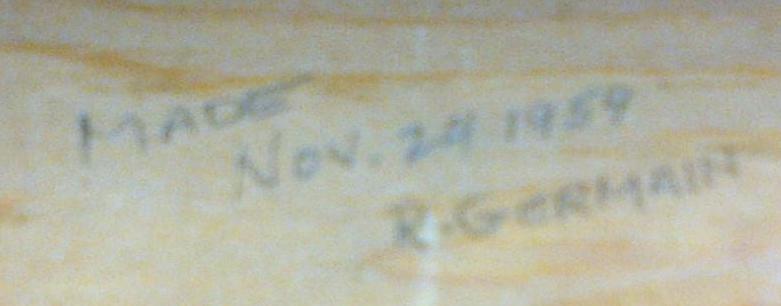

It's not a Studley Box but my Uncle Ralph made it. He even signed

it:

1959.

This was a handy and useful change - though you can still see tool boards at the

This was sufficient for a while until the inevitable happens...I acquired more tools

I built a multi-door box that hung on French Cleats. It was 10" deep and had 2 outer

You open up one door...you block the door of the cabinet next to it. Need a wrench?

I lived with this for a while until I could think of something better.

One idea that appealed to me was the concept of sliding tool boards. In one Small Shop

Since they are bypass doors, you can have 2 layers of doors one in front of the other.

So what I decided to do was to cut the 10: carcass in half to make 2, 5" deep carcasses,

The finished system looks like this:

As I made these sliders I took careful note as to which tools I used, and in what order. Standing at the man bench and looking left the rarely used tools are the furthest away from me:

Standing at the main bench, I can reach the slider you see with the screwdrivers.

In front of the main bench are two bypass sliders each of which are half the width of the

But I noticed that my workflow is typically:

The tools got dusty, so I had to occasionally cleaning/vacuum the tools. On top of that I never

reconfigured the tools on the boards nor did I move the boards to get the tools I needed closer to me.

So the advantages were nullified.

Next.....

Back To Top

Uncle Ralph's Cabinet:

My uncle was a good woodworker and also machinist. He built a tool cabinet which my

cousin offered to me after he passed away. I grabbed it immediately.

Well this is a keeper. So I hung it over the main bench

with french cleats and populated the cabinet:

left of the picture. Also as you see on the right, the door could not fully open

because of the plane storage wedge on the extreme right. And when the door was open

I couldn't get to the planes.

And then I acquired an airplane and started to do some sheet metal work.

I acquired sheet metal and tube bending tools and Uncle Ralph's tool box

now holds those.

What to do?

Multi-Surface Tool Cabinet:

Build a tool cabinet of course.

doors. Opening the outer doors revealed two more doors which also swung open:

The inner door had tools on either side of the door and if you open that door you

revealed the back of the carcass where my planes were stored:

using it for a while I was still not satisfied. I was forever flipping doors.

However, this picture shows the main problem:

That's in the left hand cabinet. Another problem was that the 10" deep cabinet cast

a shadow on the work bench creating a dark space underneath it. I had to mount a light

on the underside of the cabinet to see (as you can see in the picture). And you had to

be careful you didn't hit the light with your backsaw.

Tool Cabinets with Sliders:

In order to think of something better I used my usual method of searching the web for ideas

There's no lack of crafty and useful ideas out there.

article someone had used sliding tool boards which ran on the same sort of tracks that

bedroom closet bypass sliding doors run on. This system has three advantages:

So I got a 9 foot section and a 3 foot section to make 12 feet of track for sliding boards

This would cover my main bench (7 feet) but extend beyond the main bench to the right

and well beyond the main bench to the secondary plywood bench to the left.

They slide past one another. Behind the two layers I have space for more storage. Seems

like a carcass ought to go in there because there are "bays" created by the 2x4's I use to

support the bench and the back wall.

:

and fasten pegboard on the back of the half which had no back:

Each slider was 26H x 22W and made from pegboard framed in pine:

As I built the sliders and played with the tool organization, any tool that I had not used

in the last few years - or ever - was sold or given away.

With 12 feet of bypass sliders, I wanted the tools I used first and most to be over the main

bench which is all the way to the right. The less I used a tool, the farther to the left is was

stored on either a slider or a carcass. I have two carcasses in 2 bays as you see above

and then I have a bay with 2 sliders all the way to the left which hold tools that I

rarely use but which I'm not quite ready to get rid of.

So when I need that slider it can be pulled in front of me or close enough.

carcass and the same height. So both cover the main carcass:

Both of these can be pushed to the right and out of the way revealing the main carcass:

So this positioning gives me access to everything I need at one time:

And if I need to make a knifewall when marking, the chisel slider is right there

on the left hand side of the picture.

Back To Top